As we continue to push the boundaries of innovation and progress, the world of manufacturing is poised for a major transformation. With the rise of advanced technologies such as artificial intelligence, robotics, and the Internet of Things, the traditional manufacturing processes are being reshaped for the better. This new era of smart and connected production promises to bring unprecedented levels of efficiency, accuracy, and flexibility to the manufacturing industry. From 3D printing to automated assembly lines, these future technologies are on the horizon and are set to revolutionize the way goods are produced. In this article, we will explore the latest developments in manufacturing technology and how they are shaping the future of this vital sector. From the potential impact on the global economy to the opportunities and challenges faced by businesses, we will delve into the implications of these emerging technologies and what we can expect to see in the near future. So fasten your seatbelts as we take a journey into the exciting realm of future technologies in manufacturing.

AI-powered robotics for increased efficiency.

One of the most promising trends in the field of artificial intelligence (AI) is the integration of AI-powered robotics in manufacturing processes. This innovation has the potential to revolutionize the industry by significantly increasing efficiency and productivity. With advanced algorithms and machine learning capabilities, AI-powered robots can perform complex tasks with precision and accuracy, eliminating human errors and reducing operational costs. These robots can also adapt and learn from their environment, making them highly versatile and adaptable to changing production needs. By incorporating AI technology into manufacturing processes, businesses can streamline operations, optimize resource allocation, and achieve higher levels of productivity and profitability.

3D printing for on-demand production.

One of the emerging technologies reshaping the future of manufacturing is the utilization of 3D printing for on-demand production. 3D printing, also known as additive manufacturing, allows for the creation of three-dimensional objects by layering materials based on a digital design. This revolutionary technique offers numerous advantages in the manufacturing industry. Firstly, it enables businesses to produce customized products quickly and efficiently, eliminating the need for large-scale production and excessive inventory. This not only reduces costs but also minimizes waste and environmental impact. Moreover, 3D printing allows for intricate designs and complex geometries that were previously challenging or impossible to achieve with traditional manufacturing methods. As the technology continues to advance, with advancements in AI future trends, we can expect even greater innovation and integration of artificial intelligence into 3D printing processes, further enhancing efficiency, precision, and creativity in on-demand production.

Virtual and augmented reality integration.

Virtual and augmented reality integration is another exciting development on the horizon for the manufacturing industry. These immersive technologies have the potential to revolutionize various aspects of the manufacturing process. With virtual reality (VR), manufacturers can create virtual simulations of their production lines, allowing them to identify and resolve potential issues before physical prototypes are created. This not only saves time and resources but also enhances overall efficiency. Additionally, augmented reality (AR) can be utilized to provide real-time information and guidance to workers, improving accuracy and reducing errors. For example, technicians can wear AR-enabled glasses that overlay instructions and visual cues onto their field of view, ensuring precise assembly and maintenance procedures. As AI future trends continue to evolve, we can expect virtual and augmented reality integration to become increasingly sophisticated and seamlessly integrated into manufacturing operations.

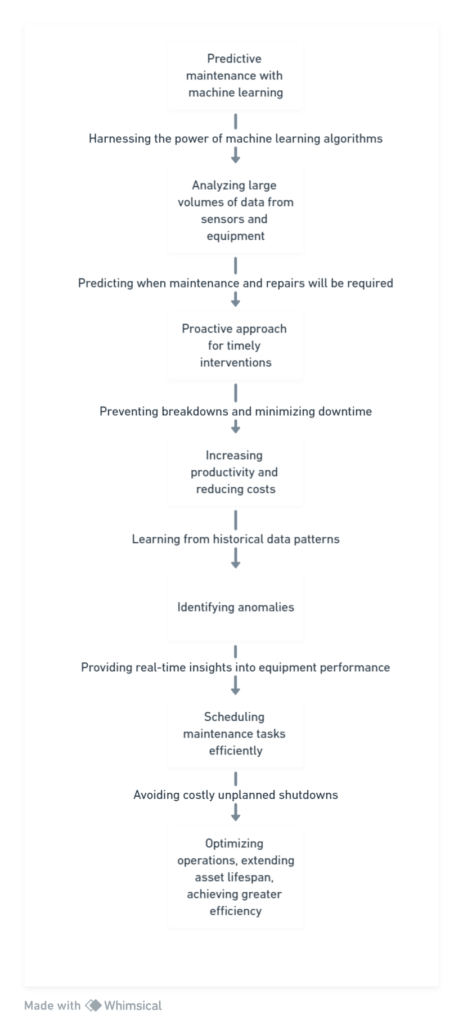

Predictive maintenance with machine learning.

Predictive maintenance with machine learning is another groundbreaking application of AI future trends in the manufacturing industry. By harnessing the power of machine learning algorithms, manufacturers can now analyze large volumes of data from sensors and equipment to predict when maintenance and repairs will be required. This proactive approach allows for timely interventions to prevent breakdowns and minimize downtime, ultimately increasing productivity and reducing costs. Machine learning models can learn from historical data patterns, identify anomalies, and provide real-time insights into equipment performance, enabling manufacturers to schedule maintenance tasks more efficiently and avoid costly unplanned shutdowns. By embracing predictive maintenance with machine learning, manufacturers can optimize their operations, extend the lifespan of their assets, and achieve greater overall efficiency in their manufacturing processes.

Advanced data analytics for optimization.

Data analytics has become a critical tool in optimizing manufacturing processes, and its advanced applications continue to shape the future of the industry. By leveraging the power of AI future trends, manufacturers can now extract valuable insights from vast amounts of data generated throughout the production cycle. These insights enable them to identify areas of inefficiency, pinpoint bottlenecks, and make data-driven decisions to optimize operations. From supply chain management to inventory control and quality assurance, advanced data analytics provides a comprehensive view of the manufacturing ecosystem, allowing manufacturers to streamline processes, reduce waste, and increase productivity. By harnessing the potential of advanced data analytics for optimization, manufacturers can achieve higher levels of efficiency, improve resource utilization, and stay ahead in an increasingly competitive market.

Automation of complex assembly processes.

In the ever-evolving landscape of manufacturing, automation is revolutionizing complex assembly processes. AI future trends have paved the way for transformative advancements in this area, leading to increased efficiency and precision. By integrating intelligent robotics and machine learning algorithms, manufacturers can automate intricate assembly tasks that were once time-consuming and prone to human error. These automated systems can handle complex operations, such as intricate component alignment and delicate soldering, with speed and accuracy. By eliminating human intervention in these processes, manufacturers can reduce costs, improve product consistency, and enhance overall production output. The future of manufacturing lies in the seamless integration of AI technologies, enabling the automation of complex assembly processes and propelling the industry into new realms of efficiency and productivity.

Smart factories with IoT integration.

As the manufacturing industry continues to embrace cutting-edge technologies, the concept of smart factories with IoT integration has emerged as a game-changer. By connecting machines, devices, and sensors through the Internet of Things (IoT), manufacturers can achieve unprecedented levels of automation, optimization, and real-time data analysis. Smart factories leverage IoT to gather and exchange data across various production systems, enabling seamless communication and coordination between different components of the manufacturing process. This integration allows for predictive maintenance, improved supply chain management, and enhanced overall operational efficiency. By harnessing the power of IoT, smart factories are shaping the future of manufacturing, ushering in an era of intelligent and interconnected production systems.

Collaborative robots for human-robot interaction.

One of the most exciting AI future trends in the manufacturing industry is the emergence of collaborative robots for human-robot interaction. Collaborative robots, also known as cobots, are designed to work alongside humans in a shared workspace. Unlike traditional industrial robots that are fenced off for safety reasons, cobots are designed to be safe and interactive, allowing for close collaboration between humans and machines. These robots can perform repetitive or physically demanding tasks, freeing up human workers to focus on more complex and creative aspects of production. Through advanced sensors and AI algorithms, cobots can detect and respond to human presence, ensuring a safe and efficient work environment. This technology holds immense potential for increasing productivity, reducing the risk of workplace injuries, and revolutionizing the way humans and robots work together in manufacturing processes.

Blockchain for secure supply chain management.

Blockchain technology has emerged as a game-changer in the realm of secure supply chain management. By utilizing a decentralized and transparent ledger system, blockchain ensures the integrity and traceability of goods throughout the entire supply chain process. With each transaction and transfer of ownership recorded on the blockchain, companies can easily verify the authenticity and provenance of products, mitigating the risks of counterfeiting and fraud. Additionally, blockchain enables real-time tracking of goods, providing stakeholders with accurate and up-to-date information on the location and condition of their shipments. This not only enhances efficiency but also enables quick identification and resolution of any potential issues or disruptions. The adoption of blockchain in the manufacturing industry holds the promise of creating a more secure, reliable, and transparent supply chain ecosystem.

Continued integration of AI technology.

With the rapid advancements in technology, the continued integration of AI technology is reshaping the manufacturing landscape. AI, or artificial intelligence, is revolutionizing the way manufacturing processes are carried out, leading to increased efficiency and productivity. One of the key AI future trends in manufacturing is the implementation of predictive maintenance systems. By leveraging machine learning algorithms, manufacturers can now accurately predict equipment failures and proactively schedule maintenance, reducing downtime and optimizing operational costs. Additionally, AI-powered robotics and automation systems are streamlining production lines, improving precision, and reducing errors. These intelligent machines are capable of performing complex tasks with speed and accuracy, freeing up human workers to focus on higher-value activities. As AI continues to evolve, it is expected to drive further advancements in manufacturing, creating smarter factories and transforming the way products are made.

As we look towards the future of manufacturing, it is clear that technology will continue to play a crucial role in driving innovation and efficiency. From the use of artificial intelligence and automation to the development of new materials and processes, there are endless possibilities for improving and reshaping the manufacturing industry. With these advancements, we can expect to see increased productivity, reduced costs, and a more sustainable approach to manufacturing. The future is bright for this ever-evolving field, and we can’t wait to see what comes next.